Loose fittings pose significant risks in homes and industries, arising from wear, vibrations, or poor installation. Regular inspections are crucial for early detection and prevention of these issues, which can lead to safety hazards and system failures. By checking for signs of movement, especially in stressed areas, and promptly tightening or replacing parts, one can ensure system integrity, extend equipment lifespan, optimize performance, avoid costly repairs, and maintain overall efficiency. Keep a well-equipped toolkit ready for such inspections.

Tighten loose fittings and connections is a crucial maintenance step for any home or facility. Understanding common areas prone to looseness, such as doors, windows, plumbing, and electrical systems, is key to preventing safety hazards and costly damages. Regular inspections play an indispensable role in maintaining structural integrity and optimal performance. This article guides you through identifying loose parts and offers practical tips, ensuring your space remains secure and efficient with minimal effort. Embrace the benefits of routine checks for a tighter, safer environment.

- Understanding Loose Fittings and Connections: Common Areas and Causes

- Benefits of Regular Inspections for Tightening These Elements

- Practical Tips and Tools for Effectively Identifying and Addressing Loose Parts

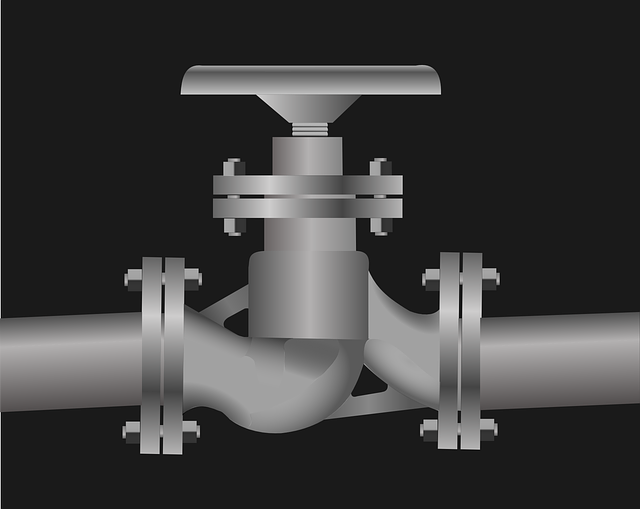

Understanding Loose Fittings and Connections: Common Areas and Causes

Loose fittings and connections are a common issue in various settings, from homes to industrial facilities. Understanding where they often occur is the first step in addressing them effectively. Common areas include doors and windows, plumbing fixtures, electrical outlets, and machinery components. The causes behind these loose connections range from normal wear and tear over time to sudden movements or vibrations, exposure to extreme temperatures, and inadequate installation practices.

Regular inspections play a crucial role in identifying loose fittings early on. By scheduling routine checks, you can prevent minor issues from escalating into major problems that may compromise safety or functionality. During these inspections, look for signs of movement, such as gaps or rattling sounds, especially in areas exposed to environmental stressors like humidity, cold, or wind. Addressing these issues promptly through tightening or replacement will ensure the longevity and reliability of your systems.

Benefits of Regular Inspections for Tightening These Elements

Regular inspections are a cornerstone of maintaining any system or machinery, and tightening loose fittings and connections is no exception. These routine checks ensure that components which may have become loosely attached over time are secure, preventing potential hazards and costly repairs. By incorporating regular inspections into your maintenance regimen, you create a robust defense against unforeseen breakdowns, enhancing the overall safety and reliability of your equipment.

Moreover, proactive tightening addresses wear and tear that naturally occurs over operation. This not only extends the lifespan of various parts but also optimizes their performance. Regular inspections allow for early detection of any issues, enabling timely interventions before they escalate. Such a proactive approach can significantly reduce downtime, increase operational efficiency, and lower maintenance costs in the long run.

Practical Tips and Tools for Effectively Identifying and Addressing Loose Parts

Regular inspections are key to maintaining any structure, be it a car, bicycle, or your home. Schedule periodic checks to identify loose parts early on. Look for any visible signs like wobbly components, rattles, or unusual noises during operation—these could indicate loose fittings.

Use the right tools tailored for the job at hand. A simple screwdriver set is essential for tightening screws, while wrenches and pliers are invaluable for handling different types of connections. Always keep a well-stocked toolkit readily available to efficiently address any loose parts encountered during inspections.